The BioCycle-D Optimized Aerobic Digestion Process provides ideal conditions for aerobic sludge digestion and the reduction of organic matter through endogenous respiration, maximizing volatile solids (VS) destruction, pathogen reduction, and sludge conditioning at a fraction of the expense of conventional aerobic digestion process. The process is also capable of producing Class B biosolids.

To learn more about BioCycle-D, watch this educational webinar.

How It Works

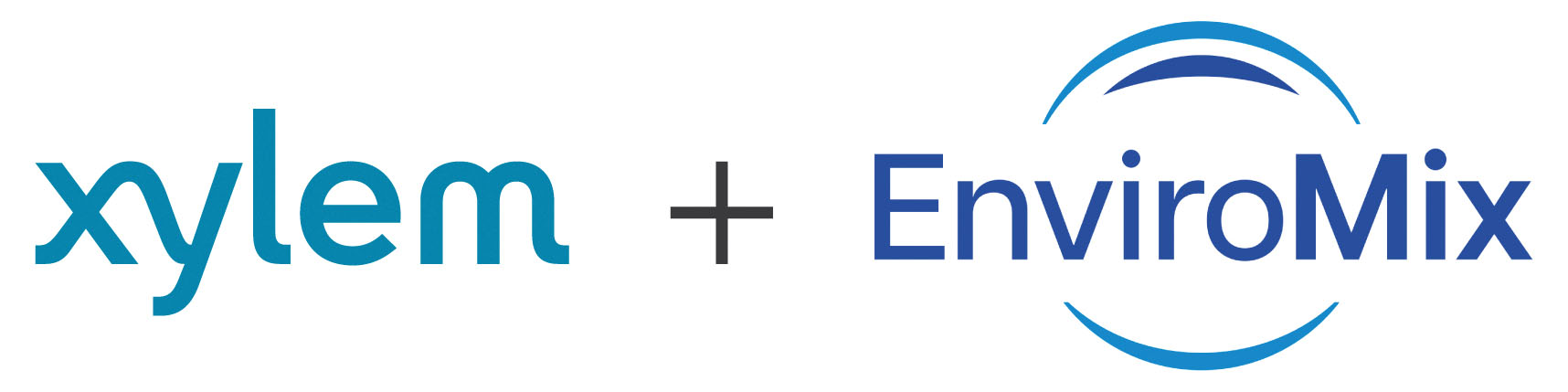

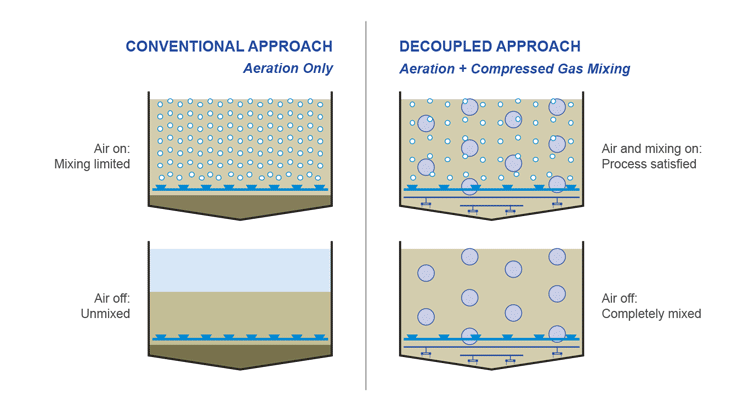

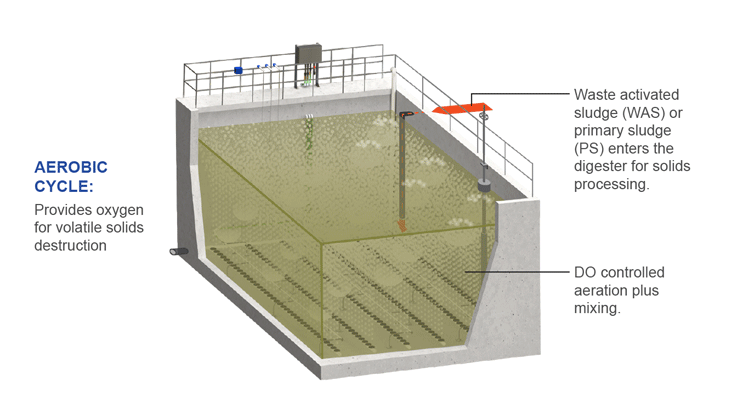

By decoupling aeration from mixing, BioCycle-D operates on the principle of alternating aerobic and anoxic conditions to optimize digestion and save energy. Through instrument feedback, the BioCycle-D controller automatically transitions the cycles from aerobic for volatile solids destruction to anoxic/anaerobic for facilitating denitrification, alkalinity recovery, and energy savings.

benefits

Click on the icons below to learn more about the process optimization, energy efficiency, straightforward operation, and unparalleled flexibility that BioCycle-D provides.

Process Optimization

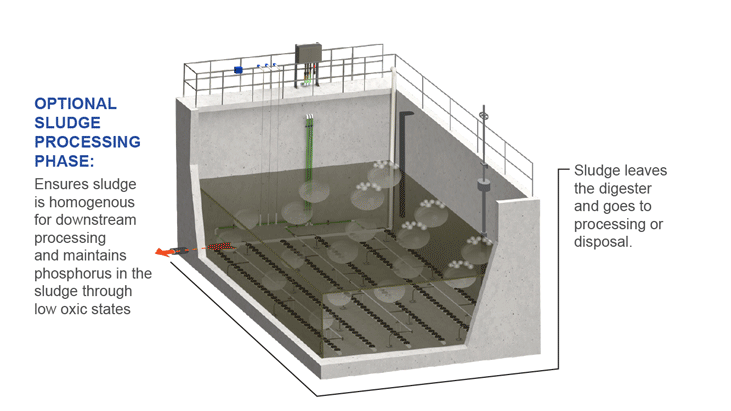

- BioCycle-D technology is able to uniformly mix sludge at concentrations up to 4% solids and meet Class B Biosolids for land application.

- Keeping contents mixed facilitates denitrification and allows for further treatment.

- Completely mixed, air off time periods allow for further conditioning of the sludge for dewatering.

- BioCycle-D provides VS destruction, whereby the amount of biomass to be disposed of is reduced.

- BioCycle-D facilitates nutrient removal and sequestration to optimize the aerobic digestion process, thus improving the treatment efficiency of nitrogen and phosphorus in the activated sludge process.

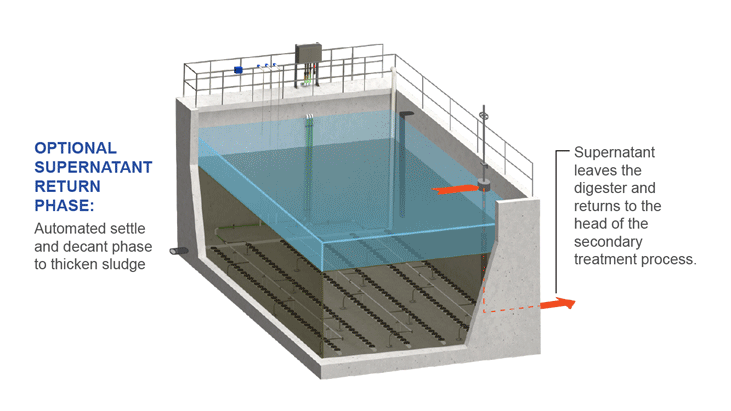

- Automatic controls adjust the process phases for variable sludge loading rates, providing significant reduction in nitrogen and phosphorus in the supernatant return stream to secondary process.

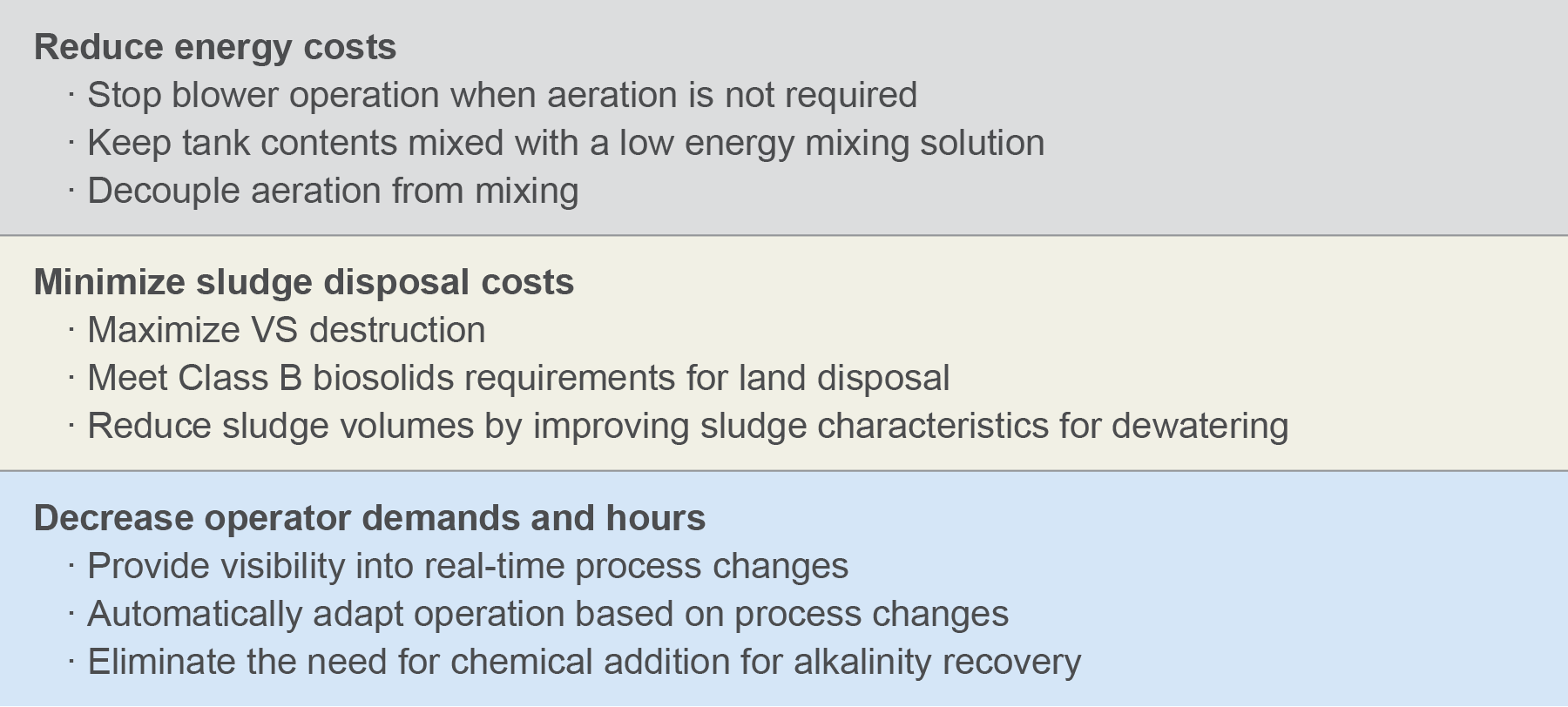

Energy Efficiency

- BioCycle-D solutions deliver 50% or greater energy savings over a conventional approach to aerobic digestion.

- Decoupling aeration from mixing allows aeration to be designed for VS destruction only, not to keep the contents of the tank mixed.

- Concurrent operation of aeration and mixing allows air to be turned down indefinitely.

- The mixing system operates at a fraction of the cost of aeration blowers.

Straightforward Operation

- Ability to mix and aerate below the grid eliminates dead zones in cone-bottom tanks.

- Through instrument feedback, the BioCycle-D controller automatically transitions the cycles from aerobic for volatile solids destruction to anoxic/anaerobic for facilitating denitrification, alkalinity recovery, and energy savings.

- By using online process instrumentation to adjust the aerobic and anoxic cycle durations based on real-time demands, reduced operator attention can be realized.

Unparalleled Flexibility

- BioMix’s patented nozzles and headers are compatible with any tank geometry or configuration.

- Circular headers conform to the slope of the tank floor, eliminating “dead spots.”

- BioCycle-D is able to accommodate a variety of sludge treatment requirements — such as parallel vs. series operation vs. options for single tank.

opportunities

Biosolids management costs for a small to medium-sized wastewater treatment facility can account for 50% of the facilities operations and maintenance expense. Upgrading the aerobic digestion process can save both time and money, while ensuring process performance to meet disposal requirements.

where it applies

Ideally suited for aerobic digesters, the BioCycle-D Optimized Aerobic Digestion Process is an excellent fit for a variety of markets — including biosolids, municipal wastewater, and industrial food & beverage. The process is a good solution for small facilities with a single tank as well as large, multi-tank plants. BioCycle-D also incorporates variable mixing intensity based on operating depth (i.e. there are no minimum depth requirements).