The FlexZone Adaptive Process Volume System is a patented, versatile secondary treatment solution that advances the conventional approach to aeration and process design by integrating BioMix Compressed Gas Mixing, diffused aeration, instrumentation, and proprietary control algorithms to ensure precise aeration control and meet treatment objectives. The FlexZone dynamically adapts anoxic, low dissolved oxygen (DO), and aerobic environments to changes in loading and temperature while optimizing the bioreactor for nutrient removal, carbon management, and energy efficiency.

To learn more about the FlexZone system, watch this educational webinar.

How It Works

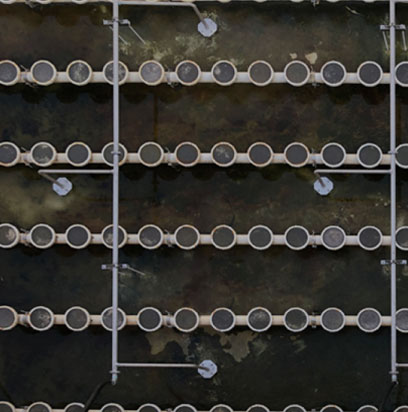

Most activated sludge treatment facilities are designed for future maximum loading, with inflexible fixed process volume environments. However, many facilities operate at a fraction of their design loading, creating operational limitations. The FlexZone solves these limitations by modifying a conventional aerobic volume to include individually controlled subzones upstream of the fixed aerobic zone, utilizing both BioMix and aeration. Independent operation of BioMix and aeration with instrumentation feedback provides precise control of the environment to meet treatment objectives in real time.

benefits

Click on the icons below to learn more about the process optimization, unparalleled flexibility, energy efficiency, and straightforward operation that the FlexZone system provides.

Process Optimization

- The FlexZone system’s individual subzone operation ensures precise aeration control while optimizing BNR.

- Dynamically matching aeration control to oxygen demand results in lower DO and nitrate in recycle streams and conserves influent carbon for EBPR and denitrification.

- The system’s low DO operation reduces aeration energy while creating an environment for simultaneous nitrification and denitrification (SNDN).

Unparalleled Flexibility

- The volume of the FlexZone and the number of subzones are custom designed based on each plant’s treatment objectives.

- The wide spectrum of operation is more advanced than the conventional approach due to the complementary equipment and automated control features.

- The FlexZone system can be designed for greenfield treatment facilities or integrated into facility upgrades utilizing existing equipment.

Energy Efficiency

- The FlexZone system eliminates airflow constraints by integrating mixing and aeration equipment, allowing for unrestricted aeration turndown and supporting environments with non-aerated mixing and SyncroMix (concurrent operation of BioMix and aeration).

- The FlexZone system ensures energy savings by automatically transitioning the aerated volume to mix and/or SyncroMix during periods of low loading.

- The system matches air delivery to meet oxygen demands while addressing mixing limited conditions.

Straightforward Operation

- Combining proprietary control algorithms with industry standard instrumentation, the FlexZone system adjusts aeration and mixing parameters to match the full range of process oxygen demand.

- The control system adjusts target DO concentrations within the FlexZone using dynamic DO algorithms, ensuring that the DO at the end of the aeration train is consistent and always meets setpoint.

why plants need the flexzone

Given that many treatment plants operate well below their design loading for years, and experience significant seasonal, temperature, or diurnal variations, ineffective carbon management and challenges with BNR including denitrification and enhanced biological phosphorus removal (EBPR) are common. Utilizing complementary mixing patterns and eliminating the need for separate tanks or baffle walls, the FlexZone system dynamically adjusts subzone operation to address changing conditions.

where it applies

Ideally suited for anoxic selectors, mixing limited tanks, and bioreactors, the FlexZone system is an excellent fit for both municipal and industrial wastewater treatment. The process is an ideal solution for retrofits of existing facilities as well as greenfield designs.