CAMix Cyclic Aerated Mixing Systems provide simultaneous aeration and mixing through a patent-pending, sequentially actuated diffused aeration system. CAMix delivers significant process benefits and substantial energy savings over conventional continuous aeration throughout the entire tank. Leveraging EnviroMix’s proven intermittent compressed gas mixing technology, CAMix introduces localized proportional air volumes to uniformly mix and aerate areas of a tank in sequence.

To learn more about CAMix, watch this educational webinar.

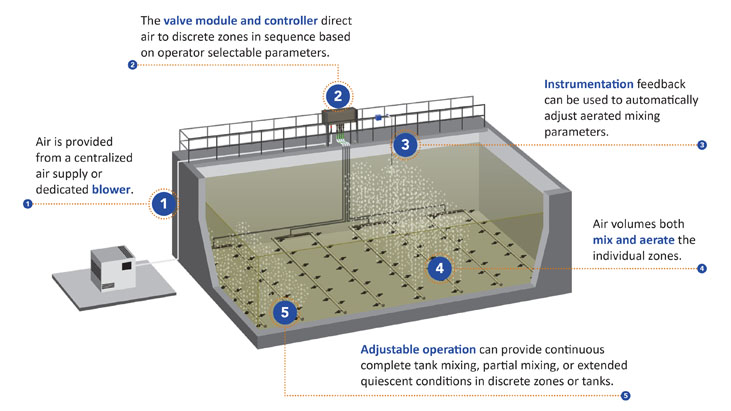

How It Works

CAMix directs air to one or more zones at a time, both mixing and aerating the individual zones sequentially. Air is provided from a centralized air supply or dedicated blower. The aeration valve module (AVM) and controller direct air to discrete zones based on operator selectable parameters. Instrumentation feedback can be used to automatically adjust parameters. Operation can be set to provide continuous complete tank mixing, partial mixing, or extended quiescent conditions in discrete zones or tanks.

benefits

Click on the icons below to learn more about the process optimization, energy efficiency, unparalleled flexibility, and straightforward operation that CAMix provides.

Process Optimization

- Uniform mixing is guaranteed with onsite performance testing.

- Aerated mixing parameters can be adjusted manually or through instrumentation feedback.

- Bottom-up mixing can provide uniformly or partially mixed conditions, as required.

Energy Efficiency

- CAMix delivers energy savings of 50% or greater over conventional continuous aeration systems.

- Unmatched turn-down capability eliminates over-aeration.

- Substantially reduced blower sizes decrease capital expense.

Unparalleled Flexibility

- Variable aerated mixing intensity is based on process parameters.

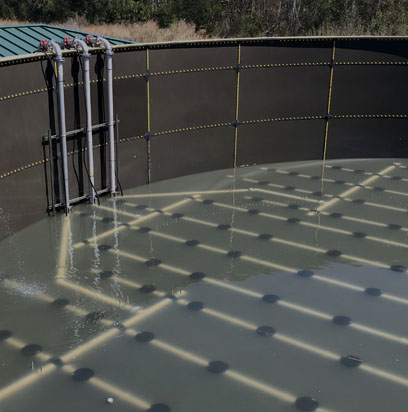

- System is compatible with any tank geometry, configuration, or depth.

- Sequential aerated mixing eliminates the need for separate aeration and mixing systems.

Straightforward Operation

- Intuitive controls adjust the aerated mixing parameters.

- No mechanical or electrical components are in the wastewater.

- Minimal maintenance items are located in accessible locations.

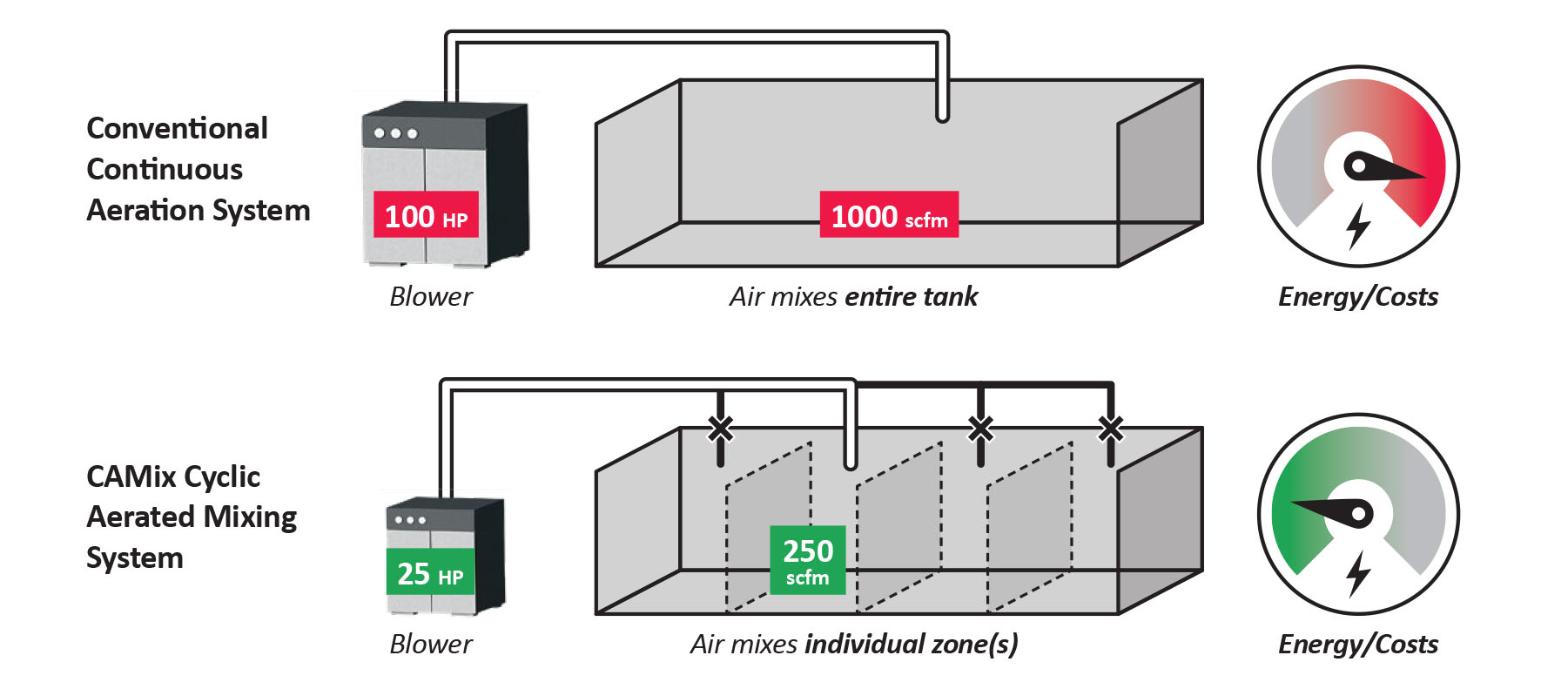

substantial savings

CAMix uniquely provides aerated mixing to meet process oxygen demands through proportional mixing air volumes. The example below uses a system designed for the industry standard 30 cubic feet per minute per thousand cubic feet of tank volume (scfm/kcf). In a conventional continuous aeration system, the blower must provide enough air to completely mix the entire tank (1,000 scfm). With CAMix, air is directed to individual zones, with the airflow rate designed around an equivalent 30 scfm/kcf per zone (250 scfm), instead of the entire tank. Energy savings of 50% or more are realized through a design using a smaller blower at lower operating horsepower (HP).

where it applies

CAMix is designed to be used in industrial and municipal wastewater and water applications, such as aerated channels, equalization tanks, sludge tanks, and aerobic digesters — or any mixing limited application that would typically incorporate a conventional diffused aeration or jet aeration mixing system.