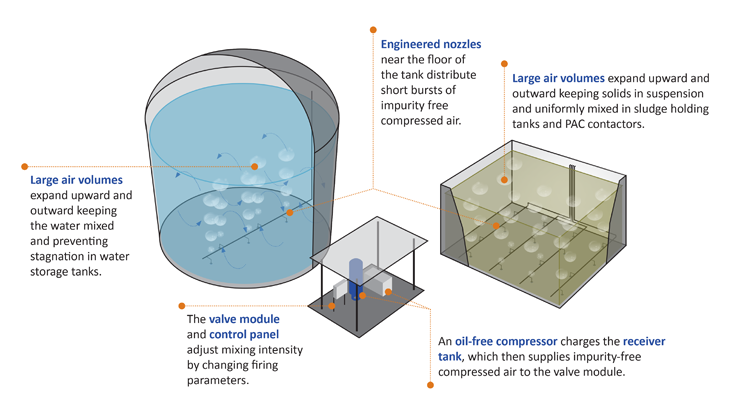

AquaBlend Potable Water Mixing Systems provide mixing of water treatment process basins and water storage tanks using impurity-free compressed air. In potable water storage tanks, mixing is an effective tool for meeting regulatory requirements for control of microbial contaminants and reduction of disinfection byproducts (DBPs). AquaBlend can also provide mixing of water treatment plant sludge tanks to maintain homogeneity and in powdered activated carbon (PAC) contactors to improve removal efficiency of unpleasant taste and odor compounds.

How It Works

AquaBlend provides mixing in water storage tanks by firing programmed short bursts of impurity-free compressed air through patented engineered nozzles. The controller air injection valve intermittently fires to blend from the tank bottom to the water surface. The large bubbles create a distinctive mixing pattern, or “tank roll.” The blending parameters of the controller may be adjusted by the operator for optimal mixing and power utilization, or the automated instrumentation feedback control system may be used.

benefits

Click on the icons below to learn more about the straightforward operation, process optimization, energy efficiency, and unparalleled flexibility that AquaBlend provides.

Straightforward Operation

- No submerged electrical components

- Non-clogging in-tank elements

- Zero in-tank maintenance

- Minimal maintenance of out-of-tank components (compressors, receivers, and air control valves) in controlled environments

Process Optimization

- Homogenization of tank contents

- Disinfection depletion slowdown

- Reduction of tank flushing and batch chlorination dosing

- Reduction of DBP formation, and taste/odor issues

- Elimination of thermal stratification

- Freezing/ice damage prevention

- Mixing suitable for concentrations up to 8% solids in sludge applications

Energy Efficiency

- Low power usage

- Greater energy efficiency than mechanical mixers

- In sludge tanks, operates at a fraction of the energy of diffused air mixing

Unparalleled Flexibility

- Bottom-up mixing in tanks of any size

- Increase of water supply quality and volume

- Variable mixing intensity based on operating depth

- No low water level limitations — able to mix at any depth

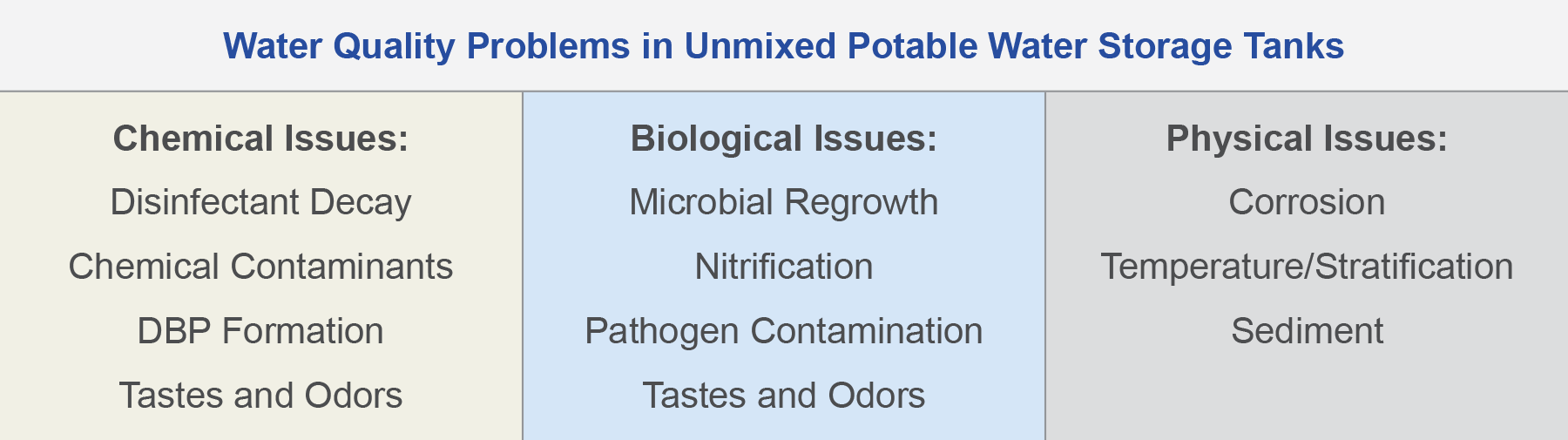

Why Mix Potable Water?

Potable water storage tanks are kept mostly full (greater than 70%) in order to maintain pressure and meet peak demand. Daily volume levels rarely fluctuate more than 10%, creating stagnant water and thermally stratified layers. Aged water can lose its disinfectant residual, resulting in bacterial regrowth and waterborne illnesses.

Where It Applies

AquaBlend Potable Water Mixing is ideally suited for numerous water treatment applications, including: Potable Water Storage Tanks, PAC Contactor Mixing, and Sludge Tanks.