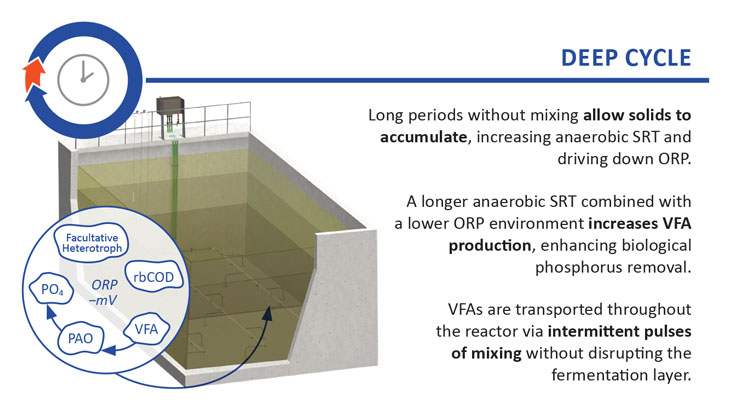

BioMix-DC Enhanced Anaerobic Mixing Systems optimize biological phosphorus removal by transforming a traditional anaerobic selector into an intensified fermentation tank by alternating a short mixing cycle with a long deep cycle. The system is designed to adapt to changing process conditions to optimize volatile fatty acid (VFA) formation and biological phosphorus removal. The deep cycle stratifies the reactor in order to increase anaerobic solids retention time (SRT), minimize oxidation-reduction potential (ORP), and maximize VFA formation. These conditions improve biological phosphorus removal.

To learn more about BioMix-DC, watch this educational webinar.

How It Works

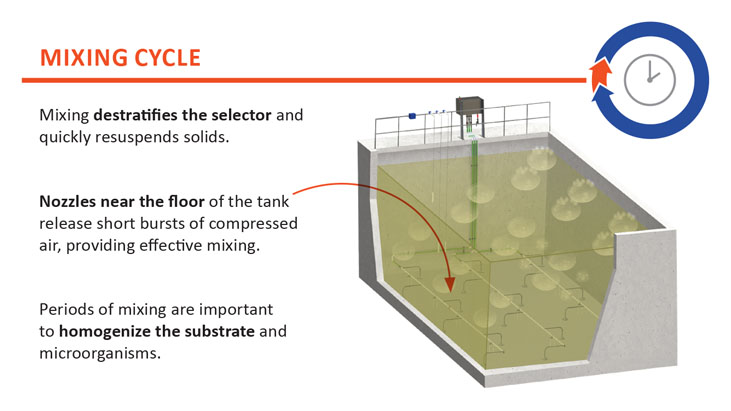

During the deep cycle, mixing is suspended for prolonged periods of time allowing for solids to accumulate, enhancing fermentation and VFA production. During the mixing cycle, intermittent mixing of tank contents is provided by bursts of compressed air fired through patented, engineered nozzles located at the floor of the tank. The cycle parameters may be adjusted to optimize mixing, power utilization, and VFA generation, manually or through automated process feedback. The operating regime of BioMix-DC is site dependent since each biological phosphorus removal treatment process operates differently based on the influent characteristics and facility design.

benefits

Click on the icons below to learn more about the energy efficiency, straightforward operation, process optimization, and unparalleled flexibility that BioMix-DC provides.

Energy Efficiency

- BioMix-DC provides energy savings of 90% or greater compared to continuous mechanical mixing in anaerobic zones.

- 40-60% less active mixing energy is required when resuspending solids compared to conventional mechanical mixing.

Process Optimization

- BioMix-DC provides proven negligible oxygen transfer.

- The system is designed to drive down process ORP.

- Operators are able to adjust mixing frequency to optimize phosphorus removal and maximize VFA formation.

Unparalleled Flexibility

- BioMix-DC easily integrates with other BioMix Compressed Gas Mixing Systems used in anoxic, swing, or post-anoxic zones.

- Cycling parameters are operator adjustable or controlled via instrumentation feedback.

- The technology is compatible with in-line mixed liquor fermentation, sidestream RAS fermentation, and sidestream mixed liquor fermentation.

Straightforward Operation

- No mechanical or electrical components are in the wastewater.

- Only non-clogging, self-cleaning parts are in the tank.

- 100% redundancy is provided by the standby compressor.

Phosphorus Removal

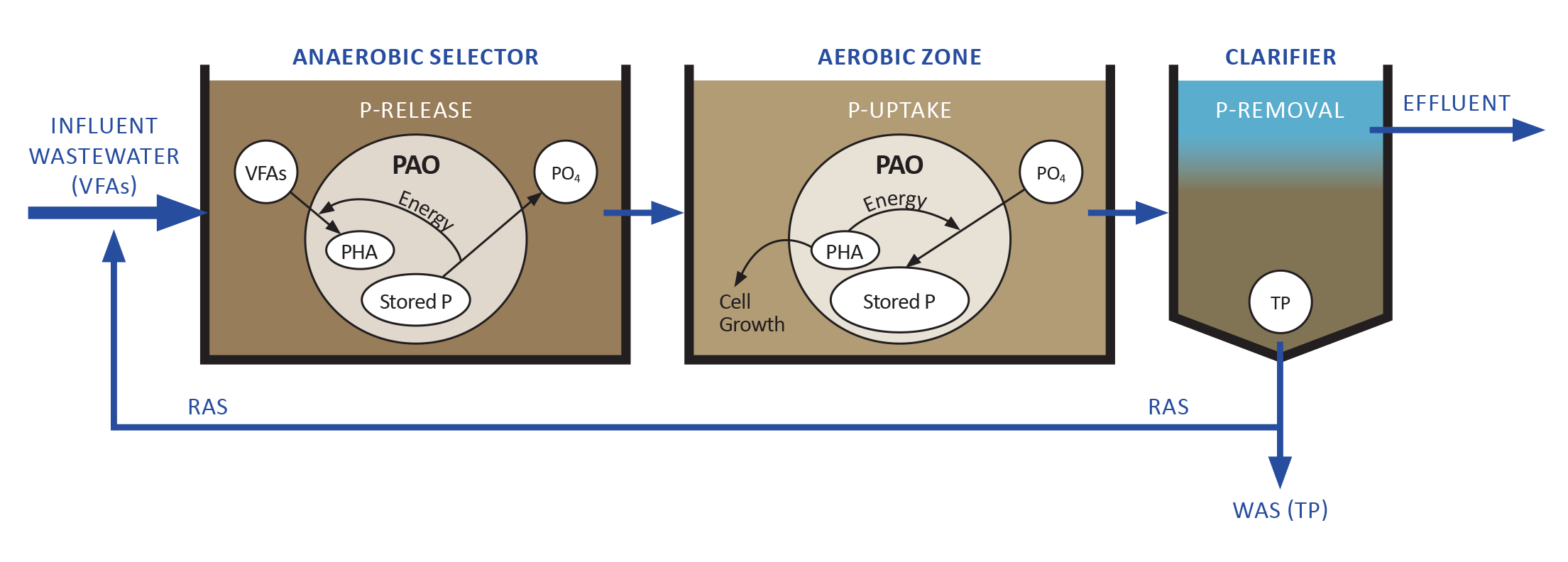

Enhanced biological phosphorus removal (EBPR) is the biological uptake of phosphorus by phosphorus-accumulating organisms (PAOs). While the actual uptake of phosphorus occurs in an aerobic environment, PAOs must first be conditioned by exposure to VFAs in an anaerobic environment. PAOs store food under anaerobic conditions and then process the stored food once under aerobic conditions. To avoid costly carbon addition, facilities with insufficient influent VFAs needed for effective phosphorus removal can encourage additional VFA production through fermentation. An anaerobic selector provides the optimal environment for the uptake of VFAs by PAOs.

Where it Applies

A BioMix-DC Enhanced Anaerobic Mixing System is ideally suited for EBPR in anaerobic selectors or fermentation tanks. The system is compatible with in-line mixed liquor fermentation, sidestream RAS fermentation, and sidestream mixed liquor fermentation.