BioCycle-ENR Activated Sludge Process is an integrated biological treatment solution utilizing activated sludge to meet stringent nitrogen and phosphorus requirements. It dynamically adapts to changing conditions by incorporating the patent pending FlexZone Adaptive Process Volume System to automatically transition anoxic, low dissolved oxygen (DO), and aerobic environments. BioCycle-ENR enables facilities to manage reactor volume in real-time to meet nutrient removal demands while improving carbon management, reducing chemical usage, and minimizing energy consumption.

To learn more about BioCycle-ENR, watch this educational webinar.

How It Works

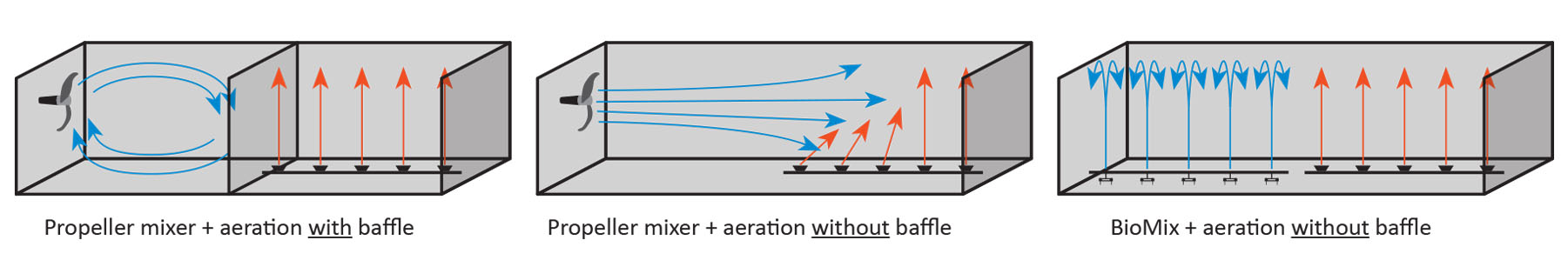

BioCycle-ENR adjusts the FlexZone volume to match the anoxic, low DO, or aerobic needs to meet treatment objectives. BioMix Compressed Gas Mixing is integrated with diffused aeration in the FlexZone system to allow for concurrent operation, as needed, during mixing limited conditions. Through online process instrument feedback, the master control panel automatically adjusts operating parameters to optimize biological phosphorus removal, nitrification and denitrification, alkalinity recovery, and energy savings.

benefits

Click on the icons below to learn more about the process optimization, unparalleled flexibility, energy efficiency, and straightforward operation that BioCycle-ENR provides.

Process Optimization

- BioCycle-ENR empowers the utility to plan for changing design conditions by matching the reactor environment to real-time demands.

- The process enables effective carbon management by preventing over-aeration and thus creating environments that foster denitrification to reduce carbon and fermentation to improve bio-P, resulting in minimized chemical consumption.

- BioCycle-ENR addresses diurnal and seasonal loading conditions in real-time by expanding or contracting anoxic, low DO, and aerobic volumes to accommodate current and future nutrient removal requirements.

Unparalleled Flexibility

- BioCycle-ENR can be designed for greenfield treatment facilities or integrated into facility upgrades utilizing existing equipment, including diffusers, blowers, and instrumentation.

- The process can be designed to easily retrofit conventional activated sludge processes, oxidation ditches, sequencing batch reactors, and BNR facilities.

- Independent aeration and mixing operation combined with automated process environment control allow the process to match the required volumetric environments to influent flows and loads throughout various operating conditions over the design life of the facility.

Energy Efficiency

- Smart process controls and independent mixing and aeration prevent over-aeration and wasted energy.

- To eliminate mixing limited conditions, SyncroMix provides simultaneous operation of mixing and aeration, further reducing energy consumption by matching oxygen supply with demand and using supplemental mixing to keep solids suspended.

- BioCycle-ENR offers unmatched aeration turn-down capability to provide optimal operation from day one through the design life of the plant.

Straightforward Operation

- BioCycle-ENR automatically adapts operation to ensure treatment objectives are met.

- The process offers minimal maintenance of in-tank components and easy access to out-of-tank equipment.

- BioCycle-ENR eliminates the restrictive hydraulic head loss of sequencing batch reactor technology, large footprint requirements of oxidation ditch technology, and limitations of separate fixed process zones associated with conventional activated sludge processes.

overcoming limitations

BioCycle-ENR enables designers to overcome the following limitations of conventional activated sludge design:

- Restrictive process volumes and environments: Conventional processes require fixed baffles and discrete equipment, resulting in limited turndown, elevated DO in return streams, and increased chemical addition. Without these restrictions, BioCycle-ENR is a highly adaptable solution.

- Limitations of swing zones: While swing zones offer some versatility, they have two major limitations — they only operate in one of two states (aeration or mixing) and they are constrained to a fixed volume and physical location. Offering boundless versatility, BioCycle-ENR acclimates to operating conditions.

- Challenges with point source mixers: Point source mixers provide fluid flow and mixing of tank contents by imparting thrust and velocity to develop a mixing pattern dependent upon fixed baffle walls. Bottom-up compressed gas mixing negates the need for baffles and maintains the integrity of the process environment.

where it applies

Ideally suited for anaerobic selectors, anoxic selectors, mixing limited tanks, and bioreactors, the BioCycle-ENR Activated Sludge Process is an excellent fit for both municipal and industrial wastewater treatment. The process is a good solution for retrofits of existing facilities as well as greenfield designs.