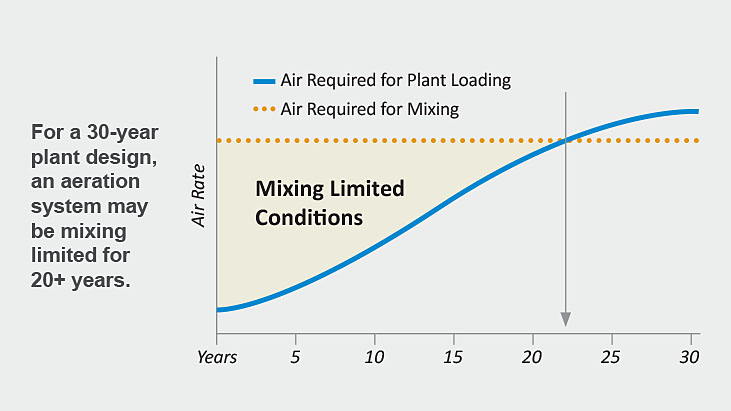

In aerobic tanks, the aeration equipment is designed to both deliver oxygen and mix the contents of the basin. Under mixing limited conditions, more air is required to mix the basin contents than is needed to satisfy the oxygen demand. Decoupling oxygen demand from mixing requirements provides the operational flexibility to reduce the airflow rate to meet the air required for plant loading.

A BioMix Compressed Gas Mixing System can be interlaced with diffused aeration grids, allowing simultaneous operation and preventing over-aeration — an outcome no mechanical mixing device can provide. This results in BNR process control benefits and significant energy savings.

The BioCycle-ENR Activated Sludge Process and FlexZone Adaptive Process Volume System are ideally suited for municipal and industrial secondary treatment processes that experience mixing limited conditions. The technologies are extremely effective for plants that are underloaded compared to design, or plants with wide diurnal variations.

Causes & Solutions

|

|

What causes mixing limited conditions?

|

|

|

How does excessive aeration impact a treatment plant?

|

|

|

Why is BioMix the right solution?The requirement for the aeration system to provide the air necessary to meet the process oxygen demand and the mixing air demand can be eliminated by decoupling oxygen demand from mixing requirements, thus providing the operational flexibility to reduce the airflow rate to meet the air required for just the plant loading. A BioMix Compressed Gas Mixing System can be interlaced with diffused aeration grids to provide mixing, allowing simultaneous operation with the aeration system at low aeration rates or independent operation. This results in:

|

resources

Application Sheet: Mixing Limited Aeration

Product Brochure: BioMix Compressed Gas Mixing System

Product Brochure: BioCycle-ENR Activated Sludge Process

Product Brochure: FlexZone Adaptive Process Volume System

Case Study: BioMix Selected for Norfolk, VA

Case Study: BioMix Selected for Exeter, NH