BioMix Compressed Gas Mixing Systems provide uniform mixing of tank contents by firing programmed, short-duration bursts of compressed air through patented, engineered nozzles located near the tank floor. The mixing parameters may be adjusted to optimize mixing and power utilization, either through operator input or automated process feedback.

To learn more about BioMix, watch this educational webinar on the Evolution of Compressed Gas Mixing, often referred to as big bubble mixing or compressed air mixing.

How It Works

A centralized compressor charges the receiver tank, which supplies compressed air to the valve module. The valve module controls the firing parameters, delivering compressed air in short duration bursts through engineered nozzles. Large air volumes expand upward and outward, providing fluid displacement without introducing measurable oxygen.

benefits

Click on the icons below to learn more about the energy efficiency, straightforward operation, process optimization, and unparalleled flexibility that BioMix provides.

Energy Efficiency

- BioMix systems provide significant power savings compared to mechanical mixers by uniformly distributing mixing energy across the basin floor rather than directing it outward from a localized point.

- Multiple studies have documented a 60% or greater reduction in power usage versus mechanical mixers and even more versus diffused air mixing.

- Mechanical mixers require at least one unit per basin, while one BioMix compressor may be used to mix dozens of tanks.

Straightforward Operation

- All in-tank components of a BioMix system are maintenance free, non-clogging, and self-cleaning.

- Systems require minimal maintenance of out-of-tank components (compressors, receivers, and air control valves) in controlled environments.

- Electrical requirements are limited to the power needed to operate the air compressor and the valve modules.

Process Optimization

- BioMix utilizes adjustable firing parameters (pressure, sequence, duration, and frequency) that enable ideal mixed conditions without deposition.

- The system provides complete mixing with proven negligible oxygen transfer.

- BioMix easily integrates with aeration equipment for swing zone and mixing limited applications.

- The technology is able to operate concurrent with or independent from aeration for optimized process conditions.

Unparalleled Flexibility

- BioMix systems are able to accommodate multiple applications, leveraging common compressors and controls.

- The technology enables mixing intensity adjustments based on process parameters.

- The system is able to mix through a range of operating depths.

- BioMix’s patented nozzles and headers are compatible with any tank geometry or configuration.

- Circular headers conform to the slope of the tank floor, eliminating “dead spots.”

- The technology is able to uniformly mix sludge at concentrations up to 8% solids.

where it applies

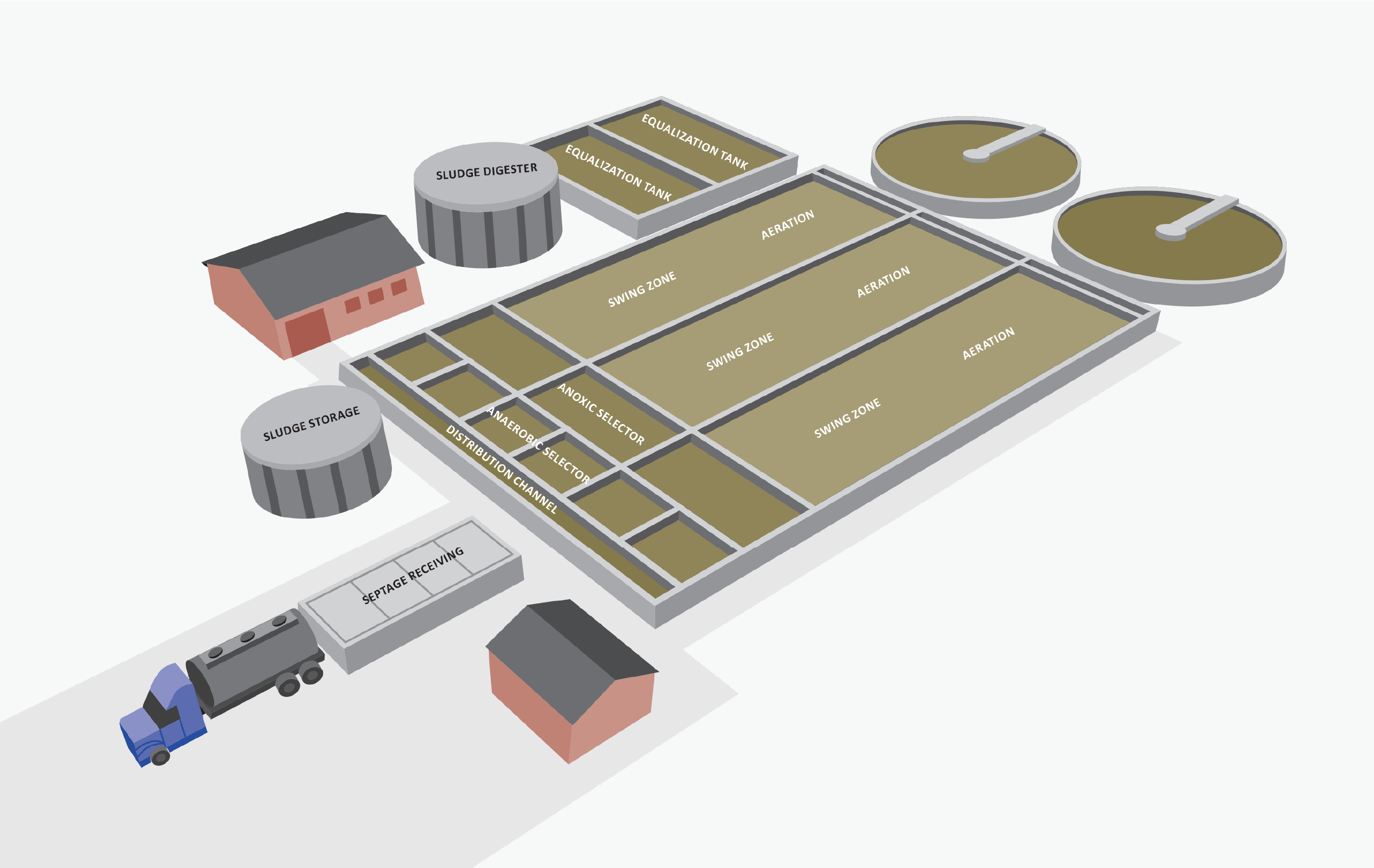

BioMix Compressed Gas Mixing System is ideally suited for numerous applications, either as a standalone system or a comprehensive system that leverages centralized compressors and controls. BioMix provides bottom up mixing through a range of depth operation and is compatible with any tank geometry or process.

Applications for the BioMix Compressed Gas Mixing System are diverse and numerous, including: